Introducing our newest innovation - the High Tension 304 Stainless Steel Wire! Crafted with precision and durability in mind, this wire is designed to withstand the toughest conditions. Made from premium quality 304 stainless steel, it offers exceptional strength and corrosion resistance, making it perfect for a wide range of applications. Whether you need it for industrial purposes, construction projects, or even for creative DIY projects, this wire is your ultimate solution. With its high tension capabilities, it ensures secure and reliable performance. Upgrade your projects with the High Tension 304 Stainless Steel Wire and experience unmatched quality and longevity.

High tension 304 Stainless Steel Wire

Stainless steel wire is an iron alloy containing at least 10.5% chromium. Its properties are obtained by the formation of an invisible, adherent film of chromium oxide. Alloy 304 is a general purpose authenticate stainless steel wire a face-centered cubic structure.

It is essentially non-magnetic in the annealed state and can be cold hardened. Its low carbon content gives it better corrosion resistance in welded structures than alloy 302.Stainless steel wire can be used in many industries.

Features

Material: 304 stainless steel soft wire, stainless steel wire is suitable for forming or building

Diameter: 0.1mm

Length: 100m

Features:smooth surface, no rusting, fine workmanship,strong and durable, not easy to break, high hardness, safe and not loose.

Benefits

corrosion-resistant,

Clean and beautiful,

Long service life,

No maintenance,

Product of small tolerances,

Flexibility.

Application

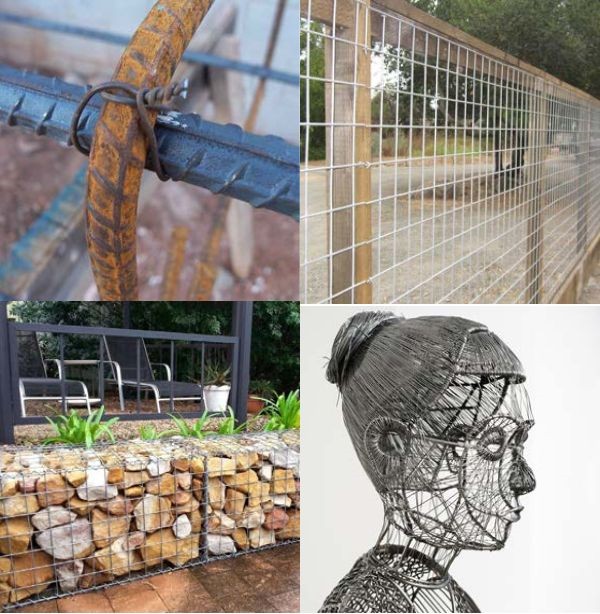

Weaving woven WIRE MESH,

Hexagonal Wire Mesh,

Spring manufacturing,

Mesh manufacturing,

Reinforcement,

Woven netting,

Food industry.

Package details

Rolls in woven bag bundles, spoon in wooden pallet or wooden frame box.

Technical specification

| Chemical property | AISI | C | Si | Mn | P | S | Ni | Cr | Mo |

| 301 | 0.15 | 1.00 | 2.00 | 0.045 | 0.03 | 6.0-8.0 | 16-18 | | |

| 302 | 0.15 | 1.00 | 2.00 | 0.045 | 0.03 | 8.0-10 | 17-19 | | |

| 303 | 0.15 | 1.00 | 2.00 | 0.2 | 0.15 | 8.0-10 | 17-19 | | |

| 304 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 8-10.5 | 18-20 | | |

| 316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.0-14 | 16-18 | 2.0-3.0 | |

| 316L | 0.03 | 1.00 | 2.00 | 0.045 | 0.03 | 10.0-14 | 16-18 | 2.0-3.0 | |

| Physical property | Nominal diameter | Surface finish | hardness | Tolerance |

| mm | inch | In mm | In inch |

| 0.30-0.40 | 0.012-1.016 | Bright/Soap coated | Half Hard or 3/4 Hard or Full Hard | ±0.008 | ±0.0003 |

| 0.40-0.50 | 0.016-0.020 | Bright/Soap coated | ±0.008 | ±0.0003 |

| 0.50-0.65 | 0.020-0.026 | Bright/Soap coated | ±0.008 | ±0.0003 |

| 0.65-0.80 | 0.026-0.032 | Soap coated | ±0.010 | ±0.0004 |

| 1.00-2.00 | 0.040-0.080 | Soap coated | ±0.015 | ±0.0006 |

| 2.00-4.25 | 0.080-0.170 | Soap coated | ±0.020 | ±0.0008 |

| 4.25-7.00 | 0.170-0.280 | Soap coated | ±0.025 | ±0.0010 |

| 7.00-16.00 | 0.280-0.630 | Soap coated | ±0.030 | ±0.0012 |