Introducing our top-quality PVC Coated wire for binding, the perfect solution for all your binding needs. This versatile wire is coated with a durable PVC layer, ensuring long-lasting performance and protection against rust and corrosion. Its strong and flexible nature allows for easy binding of documents, reports, or presentations, making it ideal for offices, schools, and home use. With a smooth surface finish, this wire provides a professional and polished look to your bound materials. Available in various sizes and colors, our PVC Coated wire for binding is a reliable and cost-effective choice for all your binding requirements.

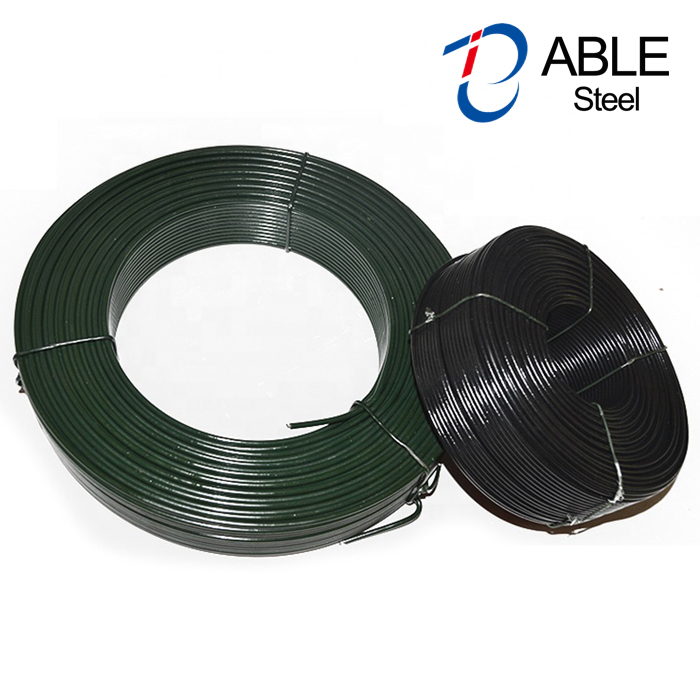

PVC Coated wire for binding

1. PVC Wire description:

PVC coated refers to a material that has been coated with polyvinyl chloride, a synthetic plastic polymer. This coating provides several benefits, including increased durability, resistance to moisture and chemicals, and improved aesthetics. PVC coated materials are commonly used in a variety of applications, including wire fencing, industrial fabrics, and outdoor furniture. The coating can be applied in a variety of thicknesses and colors to meet the specific needs of the application. Overall, PVC coated materials offer a cost-effective and versatile solution for many different industries.

2. PVC coated wire specification:

Materials before PVC coating: steel wire, Galvanized Wire, redrawing wire, annealed wire, etc.

Surface: plastic covering or plastic coating.

Color: green, blue, gray, white and black; other colors also available on request.

Average tensile strength: 350 N/mm2 – 900 N/mm2.

Elongation: 8% – 15%.

Wire diameter before coating: 0.6 mm – 4.0 mm (8–23 gauge).

Wire diameter with coating: 0.9 mm – 5.0 mm (7–20 gauge).

Plastic layer: 0.4 mm – 1.5 mm.

Wire diameter tolerance: ±0.05 mm.

Differences between plastic/PVC coating and PVC dipping:

Plastic coating is a technical processing referring to the surface processing of the metal wire. The solid plastic is melt into liquid plastic under high temperature, then the metal wire material is put into plastic flow, it is taken out after certain time. Plastic dipping is a process referring to the surface treatment on the finished steel WIRE MESH. Welded wire mesh or woven wire mesh is treated with PVC dipping to achieve further protection from the weather and better anti-corrosion property.

3. PVC coated wire features:

1. Durability: PVC coated wire is highly durable and can withstand harsh weather conditions.

2. Corrosion Resistance: The PVC coating on the wire provides excellent protection against corrosion, making it ideal for use in outdoor applications.

3. Flexibility: The PVC coating adds flexibility to the wire, allowing it to be easily bent and shaped without breaking.

4. Electrical Insulation: The PVC coating provides electrical insulation, making it ideal for use in electrical applications.

5. Aesthetically Pleasing: The PVC coating comes in a variety of colors, making it an aesthetically pleasing option for fencing and other decorative applications.

6. Easy to Clean: The smooth surface of the PVC coating makes it easy to clean and maintain.

7. Cost-Effective: PVC coated wire is an affordable option for a variety of applications, making it a cost-effective choice for many users.

4. PVC coated wire application:

PVC coated wire is commonly used in various industries such as construction, agriculture, and manufacturing due to its durability and resistance to corrosion. Some of the common applications of PVC coated wire include:

1. Fencing: PVC coated wire is widely used in fencing applications due to its strength and resistance to weathering and rust. It is commonly used in chain link fences, welded wire fences, and other types of fencing.

2. Agriculture: PVC coated wire is used in agricultural applications such as animal enclosures, poultry cages, and vineyard trellises. It is ideal for these applications as it is resistant to rust and can withstand harsh weather conditions.

3. Electrical: PVC coated wire is used in electrical applications such as wiring for lighting fixtures, appliances, and machinery. The PVC coating provides insulation and protection against moisture, chemicals, and abrasion.

4. Automotive: PVC coated wire is used in automotive applications such as wiring harnesses and battery cables. The PVC coating provides protection against abrasion, chemicals, and heat.

5. Packaging: PVC coated wire is used in packaging applications such as wire ties and twist ties. The PVC coating provides durability and flexibility, making it ideal for securing packages and bags.

Overall, PVC coated wire is a versatile material that can be used in various applications due to its durability, resistance to corrosion, and flexibility.

5. PVC coated wire packing

PVC coated wire is often used in various industries, such as construction, agriculture, and manufacturing. When packing PVC coated wire, it is important to ensure that it is protected from damage during transportation and storage. Here are some

common packaging options for PVC coated wire:

1. Spools: PVC coated wire can be wound onto spools, which are then wrapped in plastic or cardboard to protect them from moisture and dust. Spools are a convenient way to store and transport wire, as they can be easily loaded onto trucks and moved around a job site.

2. Coils: PVC coated wire can also be coiled and tied with wire or twine. Coils are a good option for smaller amounts of wire, as they are easy to handle and store. They can also be stacked on pallets for shipping.

3. Bundles: PVC coated wire can be bundled together using wire or plastic ties. Bundles are a good option for larger amounts of wire, as they can be easily moved with a forklift or other equipment. They can also be wrapped in plastic or cardboard to protect them during transportation.

4. Reels: PVC coated wire can be wound onto reels, which are then placed on a pallet and wrapped in plastic or cardboard. Reels are a good option for larger amounts of wire, as they can be easily loaded onto trucks and shipped long distances.

No matter what packaging option is chosen, it is important to ensure that the PVC coated wire is protected from damage during transportation and storage. This will help to ensure that it arrives at its destination in good condition and is ready for use.