Introducing our Galvanized Hanger Wire Clothes Hanging Wire – the superhero of all hangers! This wire is so tough, it can handle the weight of your entire wardrobe without even breaking a sweat. It's like having a personal bodyguard for your clothes, ensuring they stay wrinkle-free and organized. Made from the finest galvanized steel, this wire is as durable as it is stylish. Say goodbye to flimsy hangers that snap under pressure and hello to the ultimate fashion defender. With our Galvanized Hanger Wire, your clothes will hang with pride, knowing they have the best support money can buy. So go ahead, give your wardrobe the superhero treatment it deserves!

Galvanized Hanger Wire Clothes Hanging Wire

Galvanized Wire is a type of steel wire that has been coated with a layer of zinc through a process called galvanization. The process of galvanization involves immersing the steel wire in a bath of molten zinc, which results in a protective layer of zinc coating the surface of the wire.

Galvanized wire is available in a range of gauges (thicknesses) and diameters, and can be used for a variety of applications. The zinc coating on the wire provides excellent protection against rust and corrosion, making it ideal for use in outdoor applications or in environments where the wire may be exposed to moisture or other corrosive elements.

Galvanized wire is commonly used in the manufacturing of fencing, mesh, and other types of wire products. It is also used in the construction industry for reinforcing concrete structures, and in the production of wire rope. Additionally, galvanized wire is often used in the production of wire baskets and containers, as well as in the manufacturing of various types of industrial equipment.

Overall, galvanized wire is a highly durable and long-lasting material that provides excellent protection against corrosion, making it a popular choice for a wide range of applications.

1,Raw Material(Wire Rod)Galvanized wire and all other WIRE MESH are manufactured by wire rod. The type of wire rod is Q195, Element Composition is as follows:C≤0.07; S≤0.023; Si≤0.09; Mn≤0.32; P≤0.025.Because This type of wire rod has less Impurities, Q195 is fit for drawing. The diameter is 6.5mm.

2,Types:

Electro Galvanized Wire/Hot-dipped Galvanized Wire/Cutting Wire/Black Annealed Wire/Binding Wire

3,Application:

1) construction binding wire

2) wire mesh weaving

3) making express way fence

4) chain link fence

5) handcrafts

4,Process:

1)Galvanized wire's first stage is Drawing.

There are two kinds of drawing machine: powder drawing and water drawing. powder drawing is fit for junior drawing(6.5mm~4.0mm). One powder drawing machine has 4 tanks and 4 molds. One tank is matched with a mold. Each of them are offered energy by a electromotor. 0.9mm(max)can be "eat" when the wire cross a mold. There are no loss of weight during drawing.

2)Galvanized wire's second stage is Anneal.

Anneal is to low the tensile strength of wire. The stove is solid and built with red bricks. The architecture of anneal stove is cuboid. Different thickness of wire require different temperature. Range is from 700°C to 900°C. Output of the anneal stove, the tensile strength is 400N~600N.

3)Galvanized wire's third stage is achlorhydria acid washing.

After the draw and anneal, the wire is thinner, softer but also much more dirty. It needs achlorhydric acid washing to remove the impurities. Achlorhydric acid washing requires water pool and achlorhydric acid pool. The density of achlorhydric acid is 17%. In the Achlorhydric acid pool, there is a chaldron used for the emission of vapor.

4)Galvanized wire's fourth stage: Zinc coating

After the achlorhydric acid pool, water pool is also necessary. In the zinc pool, displacement reaction is chemical and uniformly distributed. The surface of wire is smooth. Because wire cross the zinc pool fast, abundant zinc coating requires 4 zinc pools.

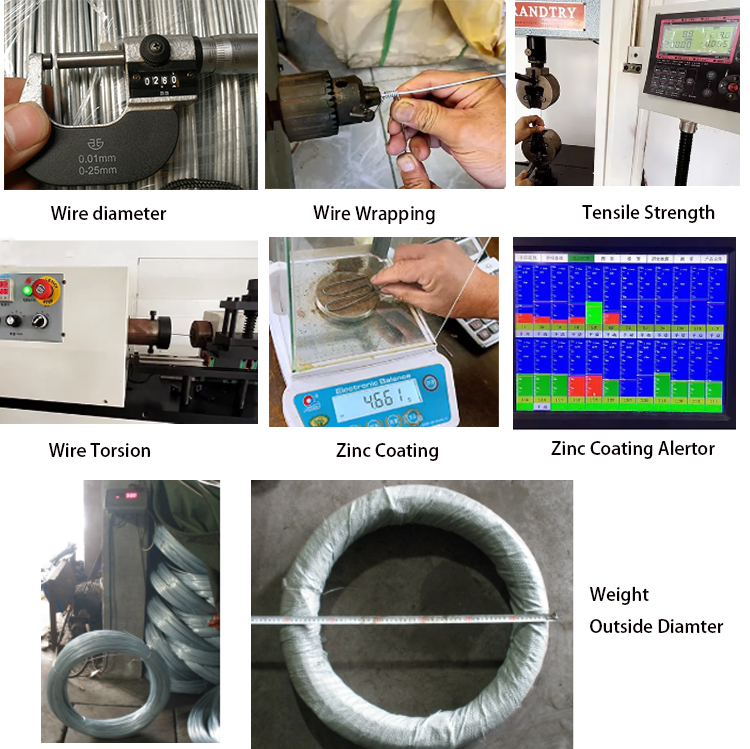

Our Products will be in highly inspection in every steps.

Loading Pics