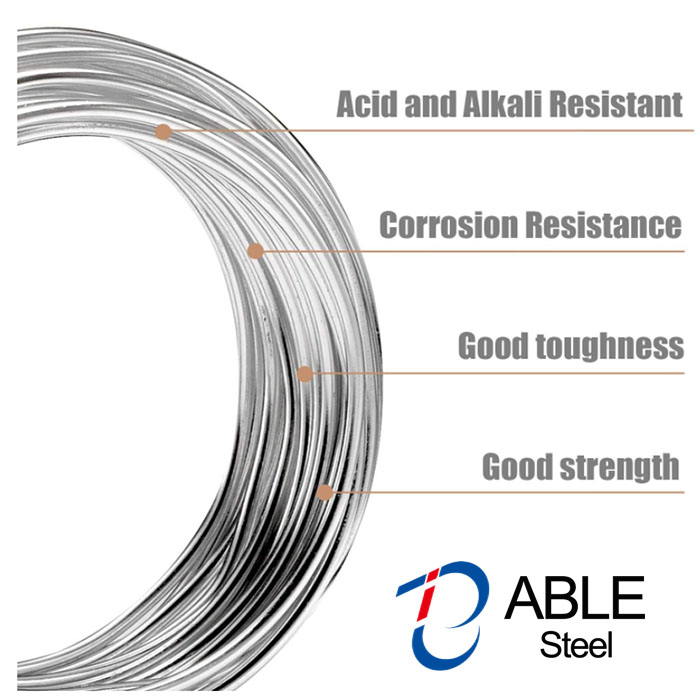

Introducing our top-of-the-line Corrosion Resistant Hot Dip Galvanized Wire, specially designed to cater to the demanding needs of the industry. Crafted with utmost precision and superior quality, this wire offers unrivaled protection against corrosion, ensuring longevity and durability in the toughest environments. The hot dip galvanization process provides a thick, uniform coating that shields the wire from rust, moisture, and other corrosive elements. Whether it's for industrial applications, construction projects, or agricultural needs, our corrosion-resistant galvanized wire guarantees exceptional performance, enhanced safety, and cost-effectiveness. Invest in the best and experience unmatched reliability with our industry-leading galvanized wire today!

Corrosion resistant hot dip Galvanized Wire for industry

Different with the electro galvanized wire, the hot dip galvanized has more better corrosion resistance. Commonly the zinc coating can reach to 40-60g/m2. But if the customer has particular requirements, we can customize more heavy zinc coating.

DESCRIPTION

It is manufactured by drawing wire rod with a low carbon content until obtaining the diameter

wanted. Subsequently, the wire goes through a galvanizing process used to

protect steel against corrosion. The zinc layer that forms on steel

provides a smooth and shiny surface.

ADVANTAGES/Features

• Longer useful life: a hot-dip galvanized product has a long life depending on

of the degree of exposure.

• It has no maintenance cost: once galvanized it is not necessary to paint or make

any maintenance.

• Greater cost-benefit ratio.

• Greater layer thickness and resistance: the alloy that is achieved provides great resistance to

bumps and scratches.

• It remains outdoors without changing its properties.

APPLICATIONS

• In the industrial sector its use is wide, all kinds of meshes, gabions, cables of

steel clips In construction it is used to tie formwork and rods. It's used

also for handicrafts, ties, merchandise packaging, corrals, vineyards, among others.

PACKAGING DETAILS

2. plastic film only

3. plastic shrink only

6. plastic woven bag

8. Wooden pallet or iron Pallet: special design to ensure the belts stable