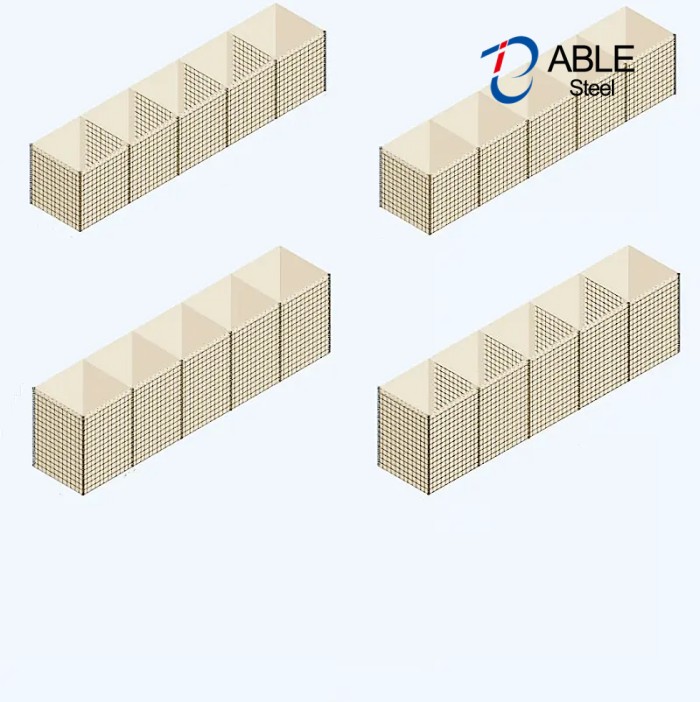

Hesco barriers are collapsible WIRE MESH containers filled with sand, soil, or other materials used for flood control, erosion control, and military fortification. They are primarily used to create temporary or semi-permanent barriers to protect against water, soil, or other potential threats. Hesco barriers are quick and easy to assemble, and they can be easily transported and stored when not in use. They are commonly used in emergency response situations, construction sites, and military operations. The production process of Hesco barriers involves several steps: 1. Material selection: The first step is to select the appropriate materials for the barriers. Typically, the barriers are made of a combination of welded wire mesh and geotextile fabric. The wire mesh provides the structure and strength, while the geotextile fabric acts as a lining to prevent soil erosion. 2. Cutting and welding: The wire mesh is cut into the desired size and shape using specialized cutting tools. The cut pieces are then welded together to form a box-like structure. The welding process ensures that the barriers are sturdy and can withstand heavy loads. 3. Geotextile lining: The geotextile fabric is cut to match the dimensions of the wire mesh structure. It is then attached to the inside of the structure using various fastening techniques such as stitching or heat bonding. The lining prevents soil particles from passing through the barrier while allowing water to drain freely. 4. Filling: Once the wire mesh structure is complete, it is filled with a suitable material such as sand, soil, or gravel. The filling material provides additional weight and stability to the barriers, making them more resistant to external forces. 5. Folding and packaging: After the filling process, the barriers are folded into a compact size for easy transportation and storage. They are then packaged in bundles or pallets, ready for shipment to the desired location. 6. Deployment: Upon reaching the deployment site, the barriers are unfolded and placed in the desired configuration. They can be interconnected to form a continuous line or stacked on top of each other to create a higher barrier. Overall, the production process of Hesco barriers involves a combination of metalworking, textile manufacturing, and filling techniques to create robust and effective barriers for various applications such as flood protection, military fortifications, and perimeter security.